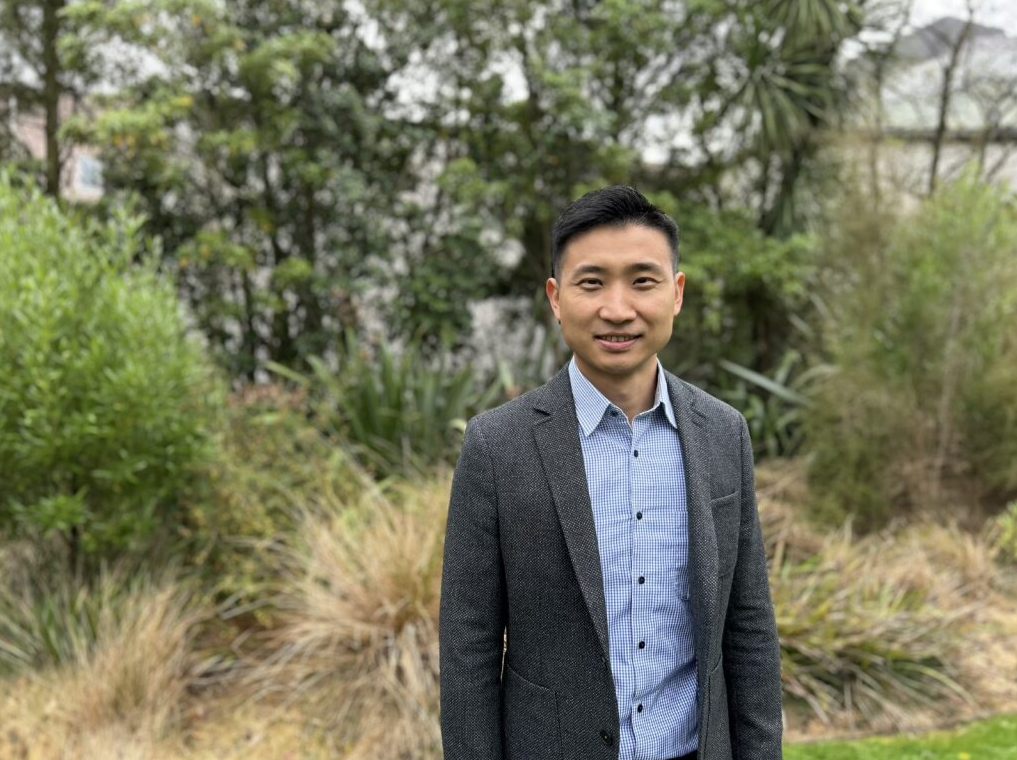

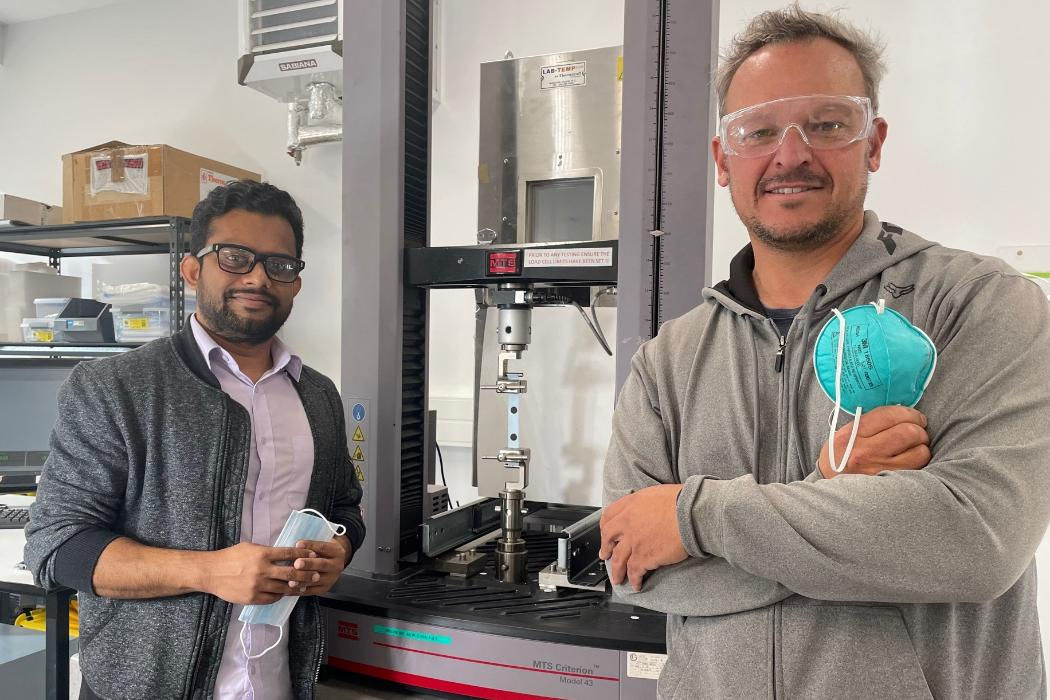

University of Canterbury (UC) PhD student Mohammad Sagor Hosen and UC Associate Professor of Materials Engineering Dr Mark Staiger who are taking part in a collaborative study aimed at disinfecting personal protective equipment for potential reuse.

UC Associate Professor of Materials Engineering Dr Mark Staiger and PhD student Mohammad Sagor Hosen are taking part in a New Zealand trial to find out whether personal protective equipment (PPE) worn by health workers as protection against Covid-19 can be decontaminated and made safe to use again.

The collaborative project, which is being led by Auckland Medical School Senior Lecturer and Taranaki-based paediatrician Dr Yvonne Anderson, began last year and aims to reduce plastic waste and address shortages of PPE. If successful, the system could increase the supply of N95 masks alone by 400 per cent.

Otago University researchers are testing the new disinfection method in a contained laboratory to determine whether it successfully inactivates the Covid-19 virus.

In the final stage of the study, Associate Professor Staiger has been charged with testing PPE materials to assess whether their safety and effectiveness is compromised by the disinfection process.

He says it’s exciting to be involved in a project that could help medical workers combat the pandemic, and has the potential to help curb the “mountains” of plastic waste created as use of PPE surges around the world.

“Generally these masks and gowns are only used once and then thrown away, and they contain plastics that can’t be easily recycled. Now that my colleagues are testing a process that might inactivate the Covid-19 virus, we need to know how many times we can disinfect and potentially reuse PPE without compromising its effectiveness.”

Associate Professor Staiger, who specialises in materials engineering, says frontline medical workers need to feel confident that disinfected masks, gowns and face shields are still safe and effective before they will reuse them.

“We are carrying out mechanical testing in the materials labs at UC to find out whether the polymers in these textiles are altered by the treatments.

“We’re also studying the filtration efficiency of N95 masks to make sure they will still block a range of viruses and bacteria.

“For surgical masks and gowns we need to verify their resistance to blood penetration. Through the project funding, we now have specialised instrumentation in our lab that directs a jet of synthetic blood at the material’s surface at a specific velocity to simulate a common scenario during surgery.”

The research aligns with Associate Professor Staiger’s other research, which focuses on new recycling methods for plastic waste and developing sustainable bio-based materials.

“In China alone there are hundreds of thousands of tonnes of PPE going to landfill each day,” he says. “At the same time, a lot of countries are running out of PPE and are having to reuse PPE multiple times, making the work of medical workers highly risky. Given this practice is already occurring globally, it is important to answer some key questions about what happens to the materials in masks over time.

The collaborative Kiwi project has $1.3 million in funding from the Ministry of Business, Innovation and Employment (MBIE) through the Covid-19 Innovation Acceleration Fund, and a $46,000 grant from the Medical Assurance Society Foundation.

The research team is currently building a mobile disinfection unit in Taranaki. The disinfection unit could then be moved in shipping containers across the country or internationally to wherever it is needed.

Associate Professor Staiger and Hosen have started carrying out benchmark testing at UC’s Ilam campus in Christchurch and hope the disinfection method and recycling of PPE for potential reuse could be ready before the end of this year.

“Everything is moving quite rapidly, as it needs to be,” Associate Professor Staiger says. “We need to make sure the treatment protocol we’re using is going to be safe for the material. If we give it the all-clear then the rest of the team can proceed with field testing. If not, then the project will shift to minimisation of medical waste as its key output.”

Hosen, who is from Bangladesh, has put his PhD research on hold to take part in the project. He says developing countries, like his homeland, are in desperate need of PPE to help manage the pandemic and he wants to use his knowledge and research to support them.

“The project we are working with may lead to valuable findings and solve a critical question, ‘Can we safely reuse PPE multiple times?’ Hosen says.

“I feel very lucky to have this opportunity to be involved, and to contribute to the fight against Covid-19.”

%20resized.jpg)