Overview and description of the technology

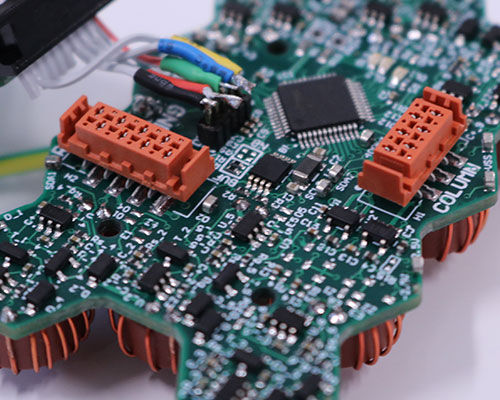

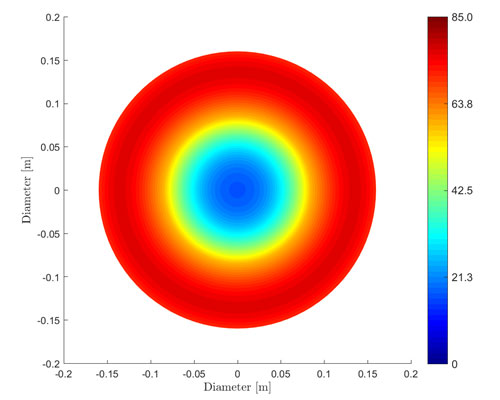

The Electric Power Engineering Centre (EPECentre) at the University of Canterbury (UC) has developed, proven, and globally patented new Smart Electrode technology that can image, among other potential applications, the wood quality of logs in less than a second. It does this by measuring the intensity distribution of electricity flowing through a log.

Technology and Benefits

Smart Electrode technology provides near-instantaneous calculations of sap- and heartwood volume and their distribution within the log. It can be deployed throughout the value chain, from the skid-site, to the processing plant, to the export wharf to inform decisions that maximise the value from each log. The Smart Electrode architecture can operate with two electric power regimes to achieve different outcomes:

- Low power regime

- High power regime

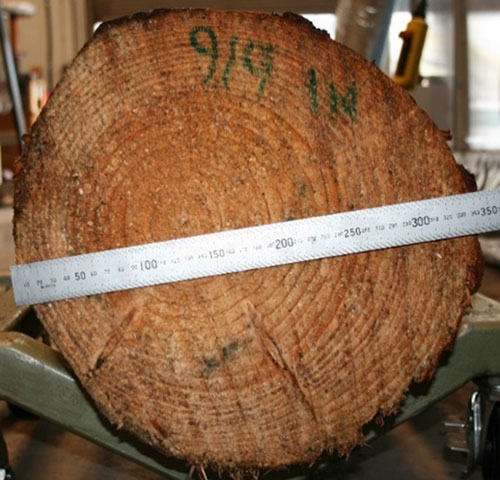

Actual log

Actual log

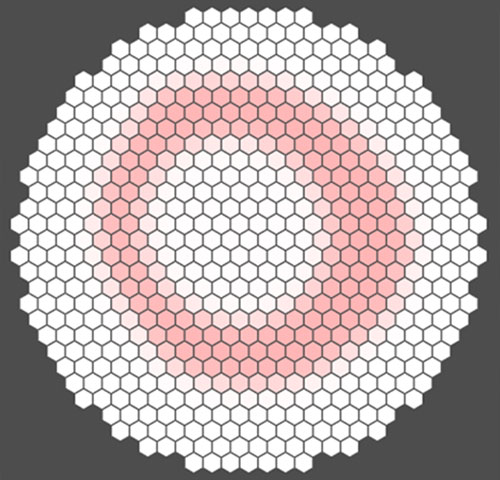

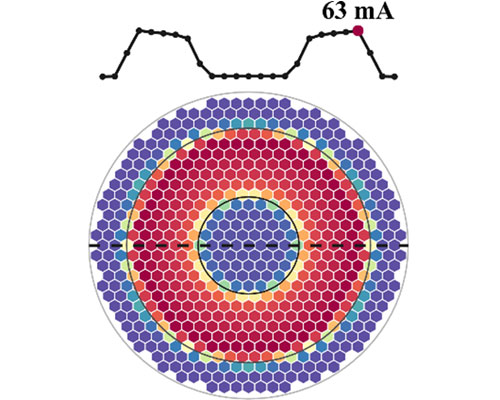

Electrical output from electrode

Electrical output from electrode

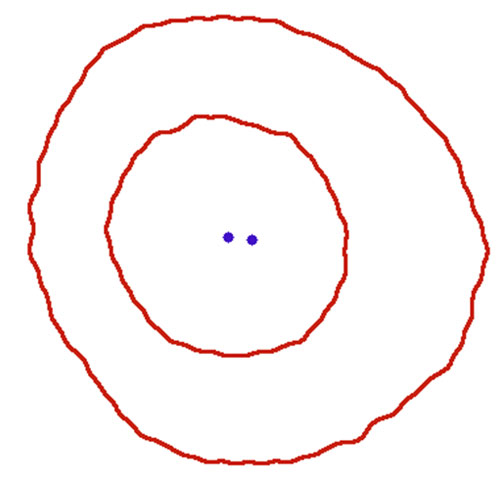

Log outline and Heartwood-Sapwood boundary with log and heartwood centroids, as calculated by Smart Electrode software

Log outline and Heartwood-Sapwood boundary with log and heartwood centroids, as calculated by Smart Electrode software

Grading and decision making optimisation

It provides a low-cost assessment tool for extracting maximum value from each log by:

- identifying optimum use, such as peeler, export or saw-log, and, if applicable, how best to saw the log into stable boards of highest value

- calculating exactly how much energy is required to heat a peeler (or export) log to required softening (or phytosanitary) temperatures and hence estimating the treatment time and cost for each processed log

- locating the optimum lathe centres to peel the longest continuous strip of sapwood, heartwood or total wood from the log. This is estimated to improve overall veneer recovery by about 15% and/or increase yield of top quality veneer by up to 20% (estimated figures based on discussions with IPL and published material from Raute Corporation, Finland).

It provides any and all of the outcomes of the low power regime, but also delivers:

- an ultra-rapid and efficient method of heat-conditioning peeler logs before the lather (likely to take about 90 minutes from plant cold start to veneer peeling, depending on log species, size and knottiness. Hot water or steam bath systems, used currently, require up to 22 hours), or:

- an ultra-rapid phytosanitary export heat treatment (~30 minutes from wharf delivery to first logs ready for ship-loading, or:

- both of the above (with a transportable machine, or suitable geographical location).

“The part of most interest to IPL is the opportunity to heat logs with in-line processing reducing the heating time from 12hrs+ to only minutes. This would be world-leading technology for both the Plywood and LVL industries. We need to see more innovation like this to move our NZ industries forward and improve the use of the NZ log resource.”

Robert Dumelow - International Panel & Lumber (West Coast) Limited - May 2020

Applications

This remarkable new technique is capable of:

- Drastically improving the speed and energy efficiency of added value timber operations as a:

- Low-cost saw or peeler log assessment tool, estimated to increase recovery value by up to 20%

- Technique to rapidly and cost-effectively heat-condition peeler logs for plywood and LVL veneer without burning wood waste.

- Diversifying New Zealand's phytosanitary treatment options for export logs as a non-chemical treatment with universal efficacy - ie heat, with the spin-off benefit of protecting export logs from the development of sap-stain.

Added value timber operations: Skid-site and Sawmills

At the skid-site

Measuring sapwood/heartwood proportions and shapes, as well as energy and time required for peeler conditioning and export treatments, to identify best use of log: sawlog; peeler; export; pulp.

Main benefits

- increased value for log harvester

- increased value for timber processor or log exporter

At the sawmill

Measuring sapwood/heartwood proportions and shape to identify best saw pattern for maximum value of sawn timber.

Main benefit

Increased efficiency and profitability of sawmills.

Added value timber operations: Plywood and LVL veneer processing plants

These plants could use both the Low and the High Power Regimes.

Low power regime

Grading and decision making optimisation.

- Calculating the energy required to heat a peeler log to required softening.

- Estimating the treatment time and cost for each log.

Main benefit

Increased efficiency and profitability of veneer product processors.

High power regime

Heat conditioning before lathe.

Main benefits

- Increase speed from plant to peeling from up to 22 hours to about 1.5 hours (depending on log species, size and knottiness).

- Transitioning the energy source from wood waste to renewable electricity.

The Export Logs sectore could use both the Low and the High Power Regimes.

Low power regime

Grading and decision making optimisation.

- Calculating the energy required to heat a peeler log to required softening.

- Estimating the treatment time and cost for each log.

Main benefit

Increased efficiency and profitability of export logs process.

High power regime

Heat conditioning before export.

Diversifying New Zealand's phytosanitary treatment options for export logs as a non-chemical treatment with universal efficacy - ie heat.

Main benefits

- Ultra-rapid phytosanitary export heat treatment (~30 minutes from cold start to logs ready for ship-loading).

- A viable and proven phytosanitary alternative to fumigants, helping to fulfil both international treaty agreements and help restore and enhance NZ's clean-green image.

- Full phytosanitary traceability, as well as log profile, as shown on the Figure in the Technology section above, to every single log shipped from NZ's shores, treated by this method, as well as potentially simultaneously removing the sap-stain problem in radiata exports.

The benefits of the Smart Electrode system for the New Zealand Economy as a whole are:

- Production or licensing of a high technology electronics-based product, with benefits for NZ engineering and export sectors. Primary wood processing, including sawmilling and peeling, is widespread globally and hence a large potential overseas market for this technology exists.

- Transitioning the energy source in veneer processing plants from wood waste to renewable electricity, allowing the currently-burnt waste to be repurposed for biofuel, chemical and pharmaceutical feedstocks, etc. This can also improve the net CO₂ position of the forest sector and potentially the country.

- A viable and proven phytosanitary alternative to fumigants, helping to fulfil both international treaty agreements and to help restore and enhance NZ's clean green image.

- Full phytosanitary traceability, as well as log profile, as shown on the Figure in the Technology section above, to every single log shipped from NZ's shores, treated by this method, as well as potentially simultaneously removing the sap-stain problem in radiata exports.

“The forest industry is interested in the technology as a long-term investment as it offers an alternative to chemical fumigants. Because it is heat-based, it will also kill insects and pathogens and there is also potential for the plywood and LVL manufacturers for both domestic and export purposes.”

Russell Dale, New Zealand Forest Owners Association R&D Manager - Winter 2020 NZ Forestry Bulletin

Funders and Partners

Publications

Media

- Joule Heating of Radiata Pine Logs [Video]

- "Electrocuting logs to kill bugs." Article published in the New Zealand Forestry Bulletin - Winter 2020 (P8-9) by the Forestry Owners Association (FOA).

Electrical Conductivity of wood

- Nursultanov, N.; Heffernan, W. J. B.; Altaner, C.; Pang, S. (2020). Anisotropic electrical conductivity of green timber within 20-90°C temperature range. Wood Science and Technology, 2020.

- Nursultanov, N.; Altaner, C.; Heffernan, W. J. B. (2017). Effect of temperature on electrical conductivity of green sapwood of Pinus radiata (radiata pine). Wood Science and Technology, 2017, 51(4):795–809.

Joule Heating publications

- Smart, T. (2020). Determining Current Distribution Within an Object Experiencing Joule Heating: Towards Application on Pinus radiata Logs. PhD Thesis, University of Canterbury, New Zealand. Embargoed until 20 May 2023.

- Nursultanov, N., Heffernan, W. J. B., Herel van, M. J. W. M. R., Nijdam, J.J. (2019). Computational calculation of temperature and electrical resistance to control Joule heating of green Pinus radiata logs. Journal Applied Thermal Engineering.

- Nursultanov, N. (2018). Joule heating of green Pinus radiata logs for phytosanitary purposes: An in-depth investigation by experimentation and computational modelling. PhD Thesis, University of Canterbury, New Zealand.

- Pawson, S.M.; Bader, M.K.F; Brockerhoff, E.G.; Heffernan, W.J.B.; Kerr, J.L.; O’Connor, B. (2018). Quantifying the thermal tolerance of wood borers and bark beetles for the development of Joule heating as a novel phytosanitary treatment of pine logs. Journal of Pest Science, July 2018.

- William J.B. Heffernan; Nurzhan Nursultanov; Ryan van Herel; Thomas Smart. (2018). Joule heating of logs for phytosanitary purposes and timber processing pre-treatment. Advanced Materials Letters, Volume 9, Issue 11, November 2018, pp. 767-775.

- Patent Application, Wood heating system and method, PCT/NZ20187/050029

- Heffernan, W.J.B. (2013) Practical application of Joule heating to the sterilization of plantation grown Pinus radiata logs. Electricity Engineers’ Association Conference, New Zealand.