Mechanical engineering labs

Mechanical Engineering has an extensive range of laboratories, facilities, and work rooms for teaching, research, and consultancy. Learn about UC's mechanical engineering labs.

Our laboratory facilities are equipped to perform a range of testing and analytical functions including:

- Hearing protection test facilities (fixtures and facility compliant with AS/NZS 1270)

- Ceiling flanking noise facility compliant with ASTM E1414

- Tyre-road noise measuring system

- Traffic noise barrier attenuation measurement system

- Low noise wind tunnel for aero acoustic measurements

- Facility for assessing human response to noise

- Duct noise test facility

- Sound intensity systems

- Environmental noise measurement and analysis facilities

- Fan noise test facility compliant with the relevant BS EN standard

Need more information?

For more information about these facilities contact:

This laboratory provides access to industrial and collaborative robots including:

- Universal Robots 7-axis UR5 robot

- Epson 4-axis G10 SCARA robot with camera system

Also available is a suite of dSPACE rapid control system prototyping equipment. This includes the following modular boards:

- DS1006 processors

- DS2002 multi-channel A/D

- DS2101 multi-channel D/A

- DS3002 incremental encoder interface

In addition, the laboratory has a number of DS1104 R&D controller boards available.

Need more information?

For more information about this facility contact:

The UCEM is the most comprehensive electron microscopy laboratory in New Zealand, with four operational electron microscopes (two scanning and two transmission). A range of short courses are available to train users within UC. External visitors are also welcome to use these facilities with training or with the assistance of our technical staff.

Internal and external users can book a session on the electron microscope after receiving training or with the assistance of our technical staff.

Book a session (authorised users only)

Electron Microscope Booking System

Laboratory equipment

JEOL JSM IT-300 variable pressure scanning electron microscope

- Oxford Aztec SDD energy dispersive x-ray analysis system

- Aztec/HKL Electron Backscattered Detector (EBSD) system

- Aztec Large area mapping and Feature software

- Forescatter and backscatter electron detectors

Philips CM200 high resolution analytical transmission electron microscope

- Single and double tilt holders

- Oxford INCA energy dispersive x-ray analysis system

- Gatan digital camera

JEOL JSM 7000F field emission, high resolution scanning electron microscope

- JEOL energy dispersive x-ray analysis system

- Backscatter electron detector

- Infrared chamber camera

- Gatan Cathodoluminescence detector

Philips CM120 transmission electron microscope (available from late 2017)

- Single and double tilt holders

Support equipment

- Gatan Pips Precision ion Polishing System

- Gatan Model 691 dimple grinder

- Fischione twin jet electro polishing unit

- Emitech K975X Coater (gold sputter and carbon evaporative coating)

- Scanner for TEM negatives

- Darkroom facilities

Need more information?

For more information about this facility contact:

The University of Canterbury Aerodynamics and Optics laboratoriesare unique in offering facilities for a wide range of studies in experimental fluid mechanics, including Sports Aerodynamics, Vehicle Aerodynamics, Atmospheric Boundary Layer studies, Aero-acoustics studies, and hydrodynamics.

The Aero lab houses two subsonic wind tunnels, the Closed-Circuit Wind Tunnel achieving wind speeds up to 200 km/h, and a low-noise Open-Circuit Wind Tunnel (one of only two in Australasia) accommodating multiple noles with conditioned flow of up to 140 km/h. Turbulence intensities are ~1% and the velocity is uniform to within 5%.

The facilities have a range of modern fully calibrated instrumentation with user-friendly manuals and readily-available expertise to streamline access and operation of the equipment. These include the 6-axis force balance, pressure probes and transducers, smoke generators, and a 6-channel hot wire instrument for air velocity and turbulence measurements. There are a range of microphones and attachments for measuring noise in airflows. There are automated traversing systems for moving sensors through a grid of measurement points.

The Open Circuit Wind Tunnel is equipped with a platform for aerodynamic measurements involving athletes and sports equipment.

The Optics lab is equipped with a fully instrumented and interfaced Particle Image Velocimetry (PIV) setup for non-invasive quantitative flow measurements, a Schlieren imaging system for studding acoustic and inhomogeneous flow density fields, and a high speed camera for imaging up to 1 million frames per second.

These facilities are used for teaching fluid mechanics, supporting Final Year Projects and postgraduate research, and are available to external users on a fee basis.

Available equipment includes:

- Aeronautical closed-circuit wind tunnel - 1.25m x 0.91m with a 2.5m long working section, max. air speed 55m/s (200kph).

- Atmospheric boundary-layer wind tunnel - 1.23m x 1.26m with a 13.1m long working section, max. air speed 26m/s (94kph) - with low noise working section.

- Six- and three- axis force balances

- Various pressure measurement systems

- Dantec miniCTA hotwire anemometry system with associated software (single and 3-axis probes)

- Smoke flow visualisation equipment.

- Various air-flow anemometers and manometers.

- StereoPIV measurement equipment with a 120mJ double pulse Nd:YAG laser, 2x TSI 4MP cameras, 2x Dantec 2MP cameras.

- Photron SA5 high speed camera.

- UAV rotor thrust rig.

Need more information?

For more information about this facility contact:

Electron Microscopy

- JEOL 7000F Field Emission Scanning electron microscope with Gatan cathodoluminescence detector and JEOL JED-2300 Energy Dispersive X-ray analysis system

- JEOL JSM IT-300 variable pressure scanning electron microscope with Oxford AZtecHKL EBSD system and Oxford Aztec SDD energy dispersive x-ray analysis system

- Philips CM200 high resolution analytical transmission electron microscope with Oxford Inca energy dispersive x-ray analysis system, Gatan CCD camera and Gatan double-tilt holder

- Philips CM120 Transmission Electron Microscope with Gatan CCD camera and Gatan double-tilt holder

Optical Microscopy

- Leica DM-IRM inverted metallurgical research microscope with digital image capture systems

- Olympus reflected light optical microscopes with image capture systems

- Olympus stereo optical microscope

Materials preparation

- Gatan Precision ion polishing system (PIPS)

- Fischione dual jet electropolisher

- Diamond saws for composite and metallic sample preparation

- Buehler Automated mounting press

- Buehler and Leco Automated polishing systems

- Carbon coaters

- Gold sputter coaters

Materials processing and treatment

- 10 kW Vacuum/Ar atmosphere induction furnace for casting high purity aluminum and magnesium alloys

- 40 kW induction furnace for steel production

- Gas-fired furnace for Al melting

- Various radiant furnaces from 200-2000°C for heat treatment and sintering

- Oil and salt quench baths

- Laboratory cold and hot rolling mill

- Pulsed Chemical Vapour Deposition Unit for thin films

- Gibitre Instruments hot press for polymer and composites manufacture with vacuum frame

- Set-up for wet lay-up and vacuum bag processing of composite laminates

- Twin screw extruder for polymer processing/compounding (owned by CAPE)

Mechanical testing

- MTS Criterion Model C43.104, Tensile/compression load frame (100 N, 500 N and 10 kN load cells, non-contact laser strain measurement, bio-chamber for fluid immersion testing, temperature chamber (< 250°C), testing of soft matter, polymers and fibres)

- MTS858, Tensile/compression load frame (2.5 kN and 10 kN load cells, pneumatic pressure controlled grips, testing of foams, polymers and composites)

- MTS810, Tensile/compression load frame (25 kN and 100 kN load cells, extensometers (8, 12, 25, 50 mm), testing of high strength metals and composites)

- Satec heavy duty tensile-compression testing rig with 1 MN load cell

- Fatigue testing (bench of 6 reverse bending rigs, hot Wohler type rig)

- Assorted hardness/microhardness testing machines (metals, polymers)

- Charpy Impact Tester for metals and advanced composites

- Thermomechanical testing

- TA Instruments, Dynamic Mechanical Analyzer (DMA) Q800 with humidity controller for viscoelasticity (damping) measurements of polymers and composites

- Perkin Elmer Differential Scanning Calorimeter (DSC) DSC8500 with robotic autosampler (automatic loading/unloading of up to 43 samples), heating rates up to 300°C/min

- TA Instruments, Thermogravametric Analyser (TGA)(CHEM Dept)

- Netzsch TMA 402 F1 Thermal Mechanical Analysis instrument capable of both elevated (up to 1500 oC) and sub-ambient temperature testing

- Zwick / Roell HIT 50P Impact Tester capable of Charpy Testing Polymer and Composite materials

Environmental testing

- BioLogic VSP potentiostat system (5-channel chassis, 3 channels/modules available), EC-Lab software, EIS analyser, 1 flat cell, Pt counter electrode, saturated calomel reference electrode, CO2 incubator for pH-controlled corrosion testing in simulated body fluids/proteins, etc.

- Microprobe electrochemical analysis system (custom-made) for microstructure-level corrosion measurements

- Hydrogen evolution measurement set-up (custom-made) for corrosion of Mg alloys

- Microscal light fastness tester

Need more information?

For more information about this facility contact:

Available equipment includes:

- Compact electrode boiler operating at up to 1.7 MPa as a steam source for a throttling calorimeter used to determine the dryness fraction of steam.

- Two self-contained refrigeration/heat pump experimental test facilities

- Two self-contained air motor experimental test facilities

- Apparatus to investigate forced convective heat transfer for air flow through a heated tube

- Capstone Micro Turbine 30kW Diesel generator set with full monitoring software. Connected with an Exhaust Heat Exchanger for experimental purposes.

- Whispergen Micro CHP, 1kW Electrical and 6kW Hot Water with performance instrumentation.

3D Printers

Stratasys Connex Objet 350 Polyjet printer. Capable of printing multiple materials at one time including elastomer, ABS like, medical and transparent. Build volume 350 x 350 x 200mm.

Stratasys Elite ABS FDM printer. Dissolvable support material. Build volume 203 x 203 x 300 mm.

5 x TierTime UP Box FDM printers. Capable of printing multiple materials including ABS, PLA, Nylon and Graphene impregnated. Build volume 255 x 255 x 200mm.

4 x TierTime Up Mini 2 FDM printers. Capable of printing multiple materials including ABS, PLA, Nylon and Graphene impregnated. Build volume 120 x 120x 120mm.

3D Scanners

Artec Eva hand held scanner. Moderate detail. Subject dimensions from the size of a football to a SUV

Artec Spider hand held scanner. Fine detail. Subject dimensions from the size of a coin to a human bust.

3D Systems Sense hand held scanner. Coarse detail. Subject dimensions from the size of a cup to a SUV

Scan to CAD software

Geomagics Design X. Used for converting scanner STL files to CAD models

Laser Cutter

MARS 1/3 sheet sheet non-metal. Cuts wood, plastics, paper, rubber etc.

Kreon laser scanner

Laser scanner matched with new Geomagic Wrap software. Suited to scanning objects in the 10mm to 500mm size range.

Need more information?

For more information about this facility contact:

Available equipment includes:

- 2 Fume hoods for Chemical preparation and Sample making.

- Large Vacuum Glove Box for Sample preparation.

- Pulsed Chemical Vapour Deposition (PCVD) reactor.

This is a restricted Access Lab, only trained operators allowed access.

Need more information?

For more information about this facility contact:

JEOL JSM IT-300 variable pressure scanning electron microscope

Kreon laser scanner

Workshop facilities

Need more information?

For more information about this facility contact:

Need more information?

For more information about this facility contact:

Students who have completed their compulsory, 35-hour workshop training course may access our undergraduate work area. Students must first seek permission and must be supervised while using the area. See Learn for more details of training courses. Find out more about workshop training requirements.

Undergraduate work area

The undergraduate work area is available for students who have completed their 35-hour workshop training course, or have been exempted from that course.

Hours

- 8.30am to 5pm

Equipment

Student access is limited to drill presses, jigsaw, sander and hand tools. Nothing is to be taken out of the work area without permission. Borrowed articles must be recorded with the borrower's name, date borrowed and date returned.

Work area users must wear safety glasses at all times, wear appropriate footwear and use hearing protection when appropriate. Users must clean up after any work done.

Workshop training facility

A qualified instructor conducts compulsory training for undergraduate students in this comprehensive facility, which is also available for postgraduate students when not being used as a training facility.

Equipment

Major items of equipment include 5 mills, 6 lathes, 2 drill presses, and hand tools. There is also MIG, stick and gas welding equipment available.

Need more information?

For more information about this facility contact:

Find out more on the Mechanical Engineering department laboratories and facilities page.

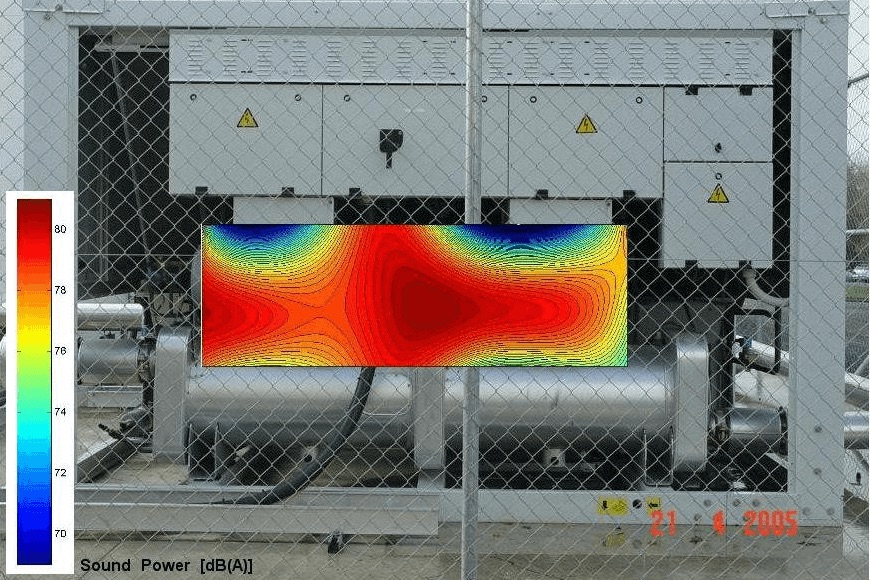

Acoustics and Vibrations Research Group

The Acoustics and Vibrations Research Group has a wide range of experience in acoustics and operates unique laboratory facilities to support its study and research relating to sound absorption, sound transmission and sound generation.

- Instrument room

- Reverberation room

- Transmission loss suite

- Low noise wind tunnel facility

- Duct test facility

- Anechoic room

- Automotive acoustics facility

- Bruel and Kjaer analysers

- Sound level meters

- Sound intensity equipment

- Noise sources and microphones

For more information see the Acoustics and Vibrations Research Group page.