Te Hiranga Pūhanga Hiko | EPECentre, a joint initiative between the electricity industry and the University of Canterbury, was established in 2002 as an entrepreneurial endeavour. It brings together industry, researchers, academia and students to foster innovation. The EPECentre has two distinct areas of operation: Research & Innovation and Education & Outreach.

-

About EPECentre

Te Hiranga Pūhanga Hiko | EPECentre is New Zealand’s pioneering research centre for electric power and clean energy applications. It's a joint initiative between UC and the electricity industry. It brings industry, researchers, academia, and students together to foster innovation. Learn more about EPECentre.

-

About EPECentre

Te Hiranga Pūhanga Hiko | EPECentre is New Zealand’s pioneering research centre for electric power and clean energy applications. It's a joint initiative between UC and the electricity industry. It brings industry, researchers, academia, and students together to foster innovation. Learn more about EPECentre.

-

About EPECentre

-

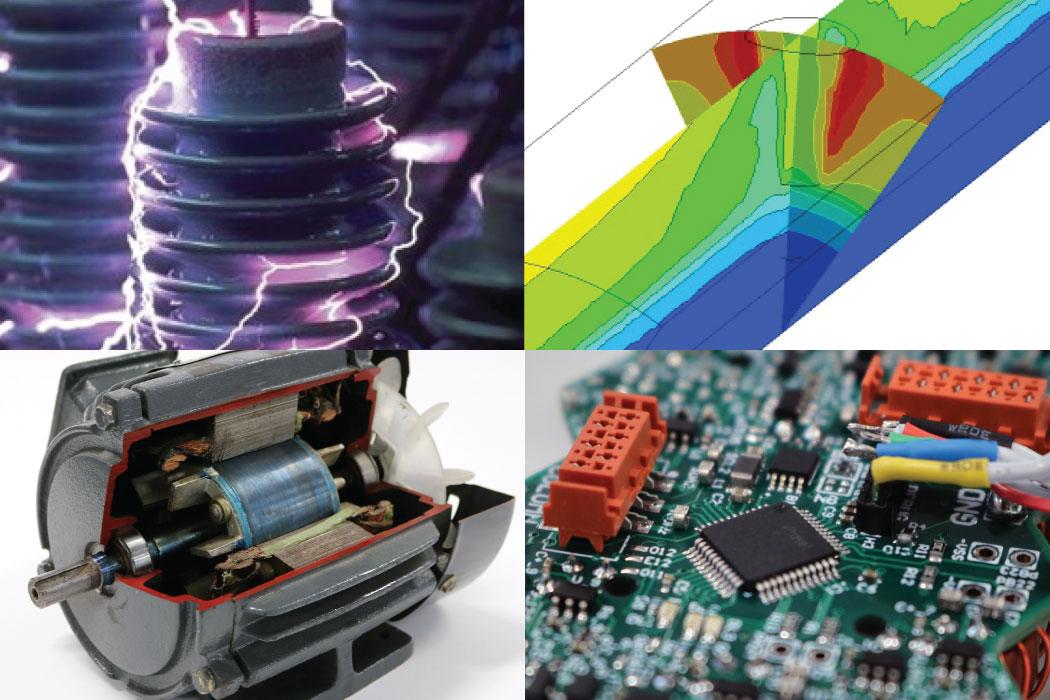

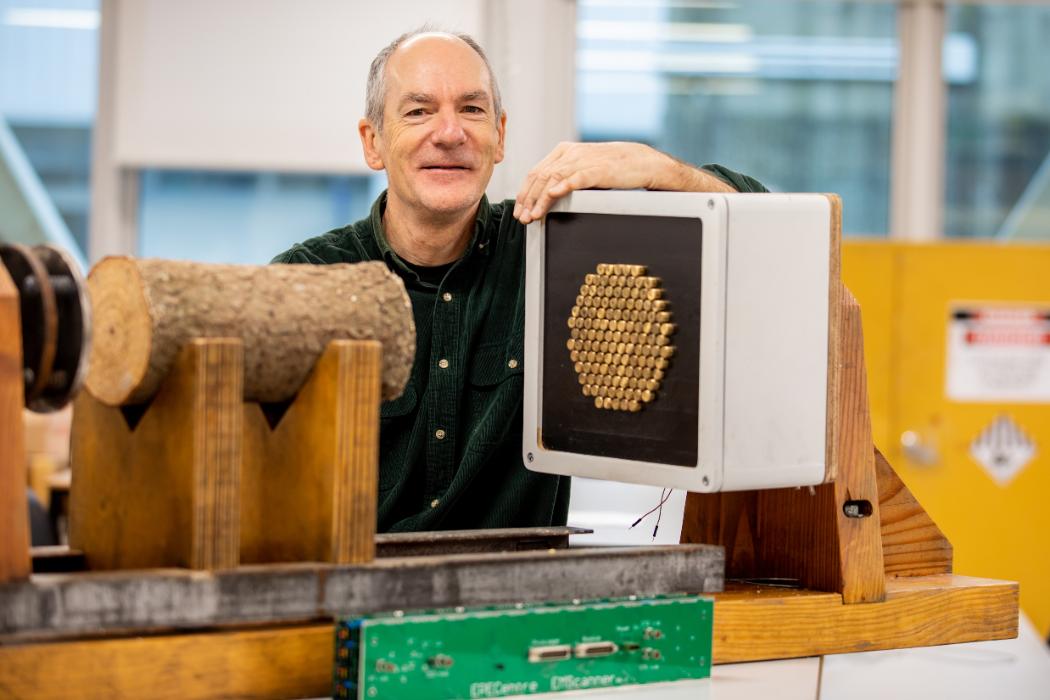

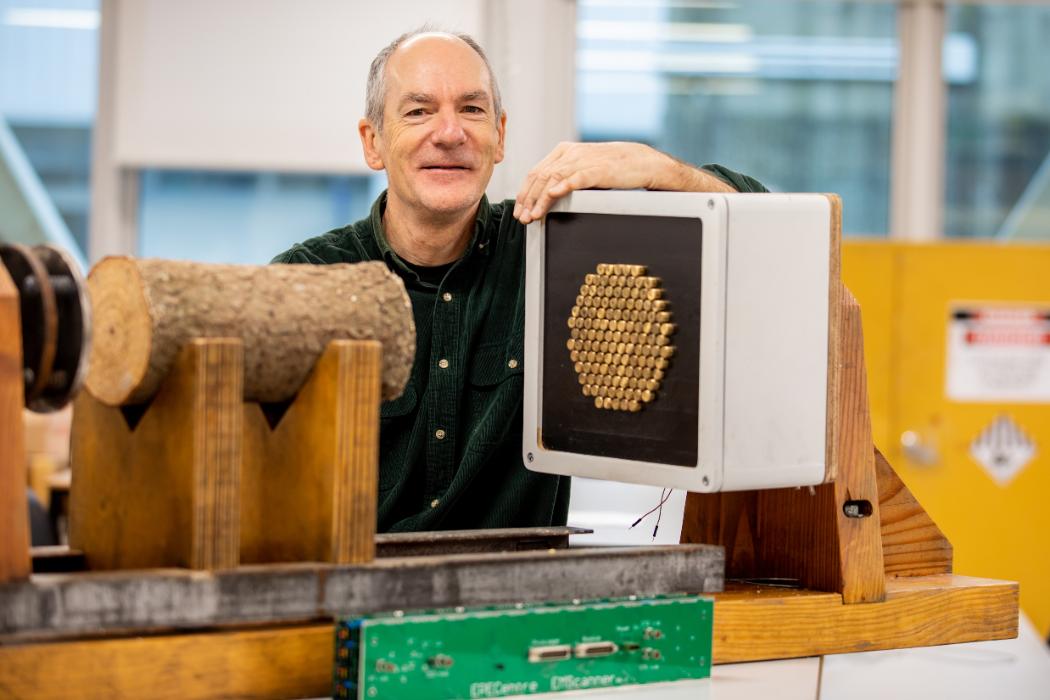

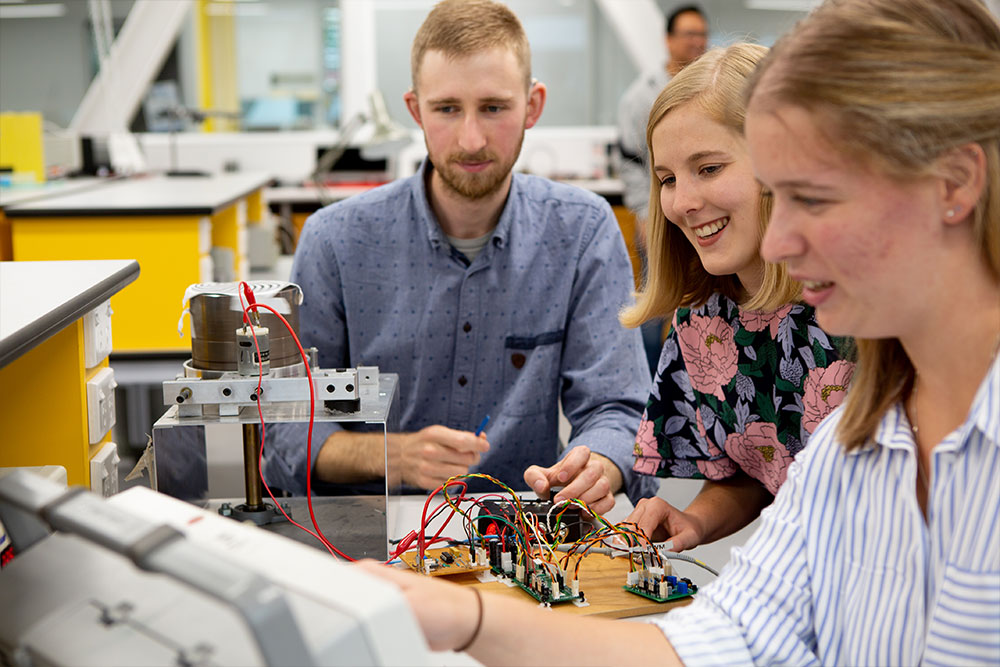

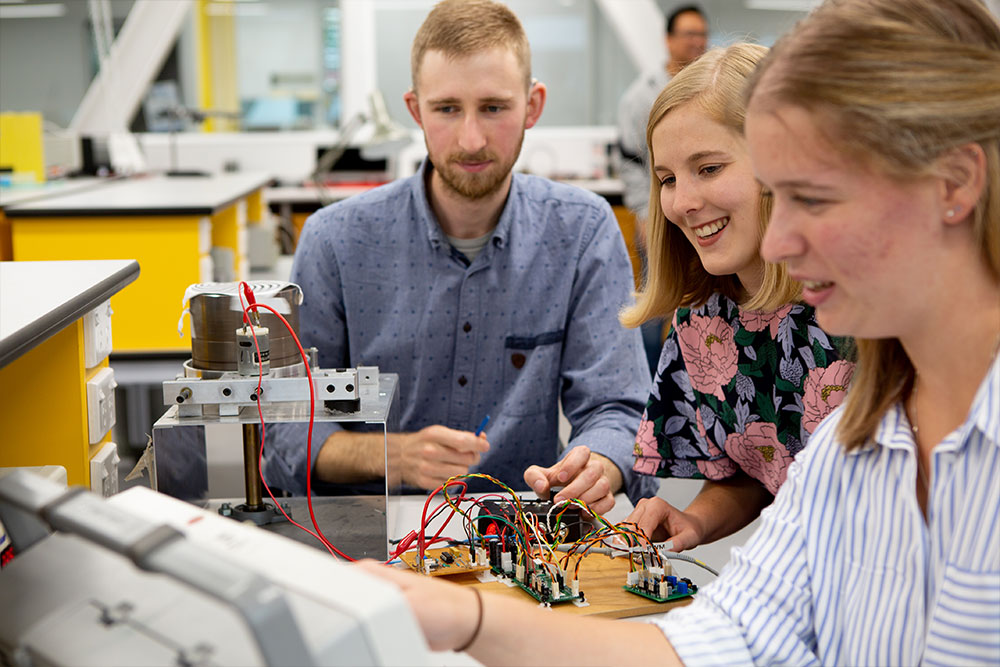

EPECentre research and innovation

UC's Electric Power Engineering Centre (EPECentre) is a world-class clean technology research incubator that fosters collaboration and innovation. We're a leading independent electric power and clean technologies research group, delivering specialist world-class research. Learn more about EPECentre research and innovation.

-

EPECentre research and innovation

UC's Electric Power Engineering Centre (EPECentre) is a world-class clean technology research incubator that fosters collaboration and innovation. We're a leading independent electric power and clean technologies research group, delivering specialist world-class research. Learn more about EPECentre research and innovation.

-

EPECentre research and innovation

-

EPECentre latest news

There's a fair bit on the go at the Electric Power Engineering Centre (EPECentre). Check out the latest news.

-

EPECentre latest news

There's a fair bit on the go at the Electric Power Engineering Centre (EPECentre). Check out the latest news.

-

EPECentre latest news

-

About Aruhiko PEET

Aruhiko – Power Engineering Excellence Trust (PEET) aims to empower those who will shape New Zealand’s energy future. We are a not-for-profit organisation established by industry and academia to foster a pipeline of power engineering talent. Our members represent many sectors of the electricity industry. Learn more about Aruhiko | PEET.

-

About Aruhiko PEET

Aruhiko – Power Engineering Excellence Trust (PEET) aims to empower those who will shape New Zealand’s energy future. We are a not-for-profit organisation established by industry and academia to foster a pipeline of power engineering talent. Our members represent many sectors of the electricity industry. Learn more about Aruhiko | PEET.

-

About Aruhiko PEET

-

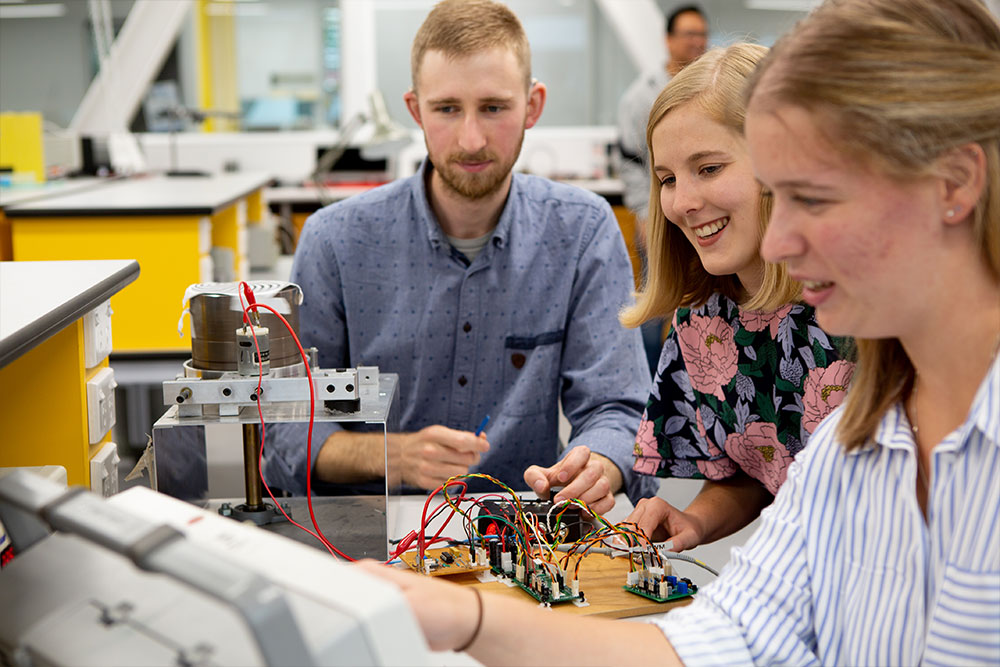

EPECentre education and outreach

UC's Electric Power Engineering Centre (EPECentre) inspires and enables tomorrow’s power engineering talent by sharing responsibility, knowledge, and opportunity across academia and industry. The EPECentre attracts students into engineering, develops talent, and connects industry with those talents. Learn more about EPECentre education and outreach.

-

EPECentre education and outreach

UC's Electric Power Engineering Centre (EPECentre) inspires and enables tomorrow’s power engineering talent by sharing responsibility, knowledge, and opportunity across academia and industry. The EPECentre attracts students into engineering, develops talent, and connects industry with those talents. Learn more about EPECentre education and outreach.

-

EPECentre education and outreach

-

Scholarships

If you're interested in Electrical and Electronic Engineering and other fields of engineering related to the power industry, there are lots of opportunities to fund your study. Scholarships are offered by EPECentre, Aruhiko - PEET, UC, our industry members, and external entities. Find out more.

-

Scholarships

If you're interested in Electrical and Electronic Engineering and other fields of engineering related to the power industry, there are lots of opportunities to fund your study. Scholarships are offered by EPECentre, Aruhiko - PEET, UC, our industry members, and external entities. Find out more.

-

Scholarships

-

Events

Find our about the various events hosted by the EPECentre.

-

Events

Find our about the various events hosted by the EPECentre.

-

Events

-

Our people

From engineers to associates, meet our people at the Electric Power Engineering Centre (EPECentre).

-

Our people

From engineers to associates, meet our people at the Electric Power Engineering Centre (EPECentre).

-

Our people

-

Contact us

There are a few ways to contact us at Te Hiranga Pūhanga Hiko | Electric Power Engineering Centre (EPECentre). See where we are on campus and feel free to get in touch if you need some help.

-

Contact us

There are a few ways to contact us at Te Hiranga Pūhanga Hiko | Electric Power Engineering Centre (EPECentre). See where we are on campus and feel free to get in touch if you need some help.

-

Contact us