Failure analysis and metallurgical engineering laboratories

The Materials Engineering Group has a diverse range of interests covering many topics within the field of materials, including ferrous and non-ferrous metallurgy, fracture and failure mechanisms, ceramics, polymers and composites. We have a history of providing research, failure analysis and testing to New Zealand Industry.

We realize that Industry needs quick results - and we are prepared to complete analyses in as little as 24 hours

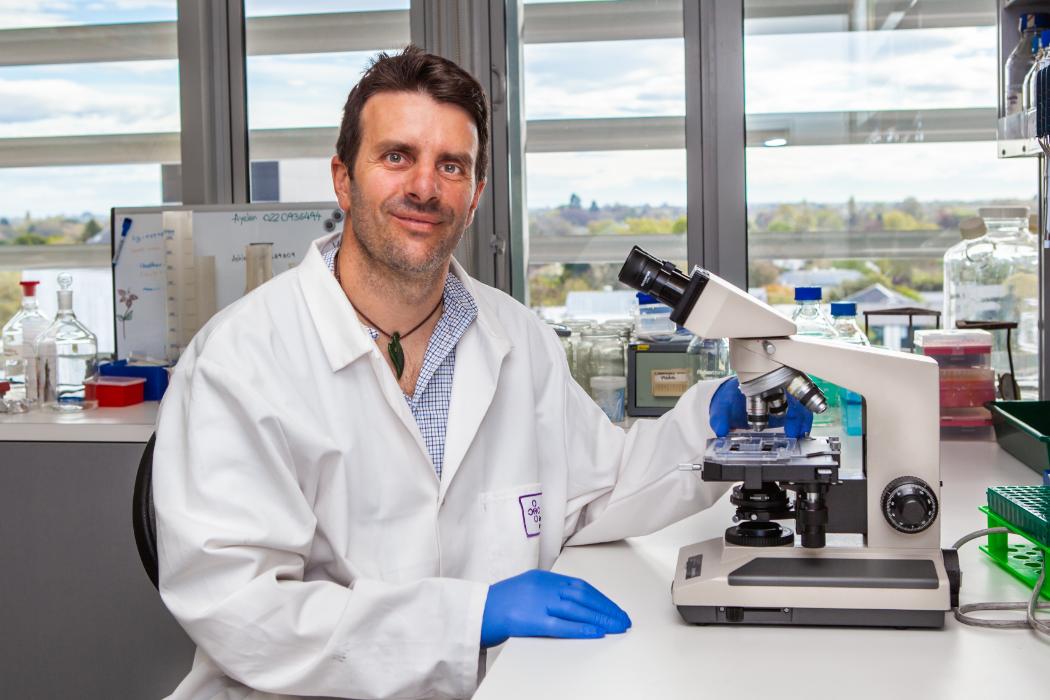

The group

The laboratory

- Leica and Olympus light microscopes with digital imaging

- JEOL Scanning Electron Microscope

- Energy Dispersive Spectroscopy

- Hitachi Transmission Electron Microscope

- TA Instruments Q800 Dynamic Mechanical Analysis (DMA) instrument

- PerkinElmer DSC8000 Differential Scanning Calorimetry (DSC) instrument

- NETZSCH TMA 402 F1 Thermal Mechanical Analysis (TMA) instrument

- MTS Criterion, MTS 858 and MTS 810 tensile/compression testing machines with load capacities from 100 N to 100 kN, including environmental chambers for temperature-controlled and fluid-immersion testing

- Satec heavy-duty tensile/compression testing machine with 1000 kN load cell

- Charpy impact tester for metals and advanced composites, and Zwick / Roell HIT 50P machine for Charpy testing of polymer and composite materials

- Assorted hardness testing machines: Brinell, Rockwell, and Vickers; LECO microhardness tester; and various durometers

- Heat treatment facilities: 10 kW vacuum/argon atmosphere induction furnace, various radiant furnaces from 200-2000°C, and oil and salt quench baths

- Creep rigs

- Cold and hot rolling mill

- Twin screw extruder

- Extrusion press and rig for magnesium alloys

- Hot press for polymer and composites manufacturing (gibitre instruments)

- Composite laminate manufacturing laboratory

- Babyplast injection moulding machine

- UniSense Microsensor Profiling System for microscale gas (H2/O2) and pH measurements

- Blood penetration testing equipment for PPE

Contact Information

Phone: +64 (3) 3 364 2596

Emails:milo.kral@canterbury.ac.nz, mark.staiger@canterbury.ac.nz

Failure analysis consultation

The Materials Group's team of engineers and technicians combines design, industrial process and material testing experience to accurately determine the root cause of product and process problems. Whatever the material, chances are we've tested it and understand its properties.

Aerospace Materials - Automotive Materials - Aluminum - Brasses - Carbon Steels - Castings - Coatings - Composites - Corrosion Resistant Steels - CVD and PVD Coatings - Elastomers - Electronic Components - Plating - Polymers - Powder Metals - Tool Steels.

The list below shows that the Materials Group can go well beyond physical testing. We test the total environment and condition of metal parts and sub-assemblies and have the equipment and the expertise to move to the microstructure level to complete the analysis process.

- Chemical composition

- Coating thickness and composition

- Materials durability and degradation

- Contamination

- Corrosion testing and analysis

- Fractography

- Mechanical testing

- Microstructural characterisation of metals, polymers and composites

- Non-destructive inspection

- Photo documentation

- Quality control

- Scanning electron microscopy (SEM)

- Weld evaluation

- Thermal and chemical analysis of plastics and composites

- Thermal expansion coefficient of materials

- Density measurements

Examples of Recent Cases

- Investigation of weld microstructures in aluminum lithium alloys.

- Failure of engine exhaust manifolds for motor homes.

- Materials selection for river lock gate applications.

- Analysis of cracked welded assembly.

- Analysis of fractured hydraulic shaft.

- Investigation of fire damage.

- Dimensional analysis of printed circuit boards.

- Failure analysis of a fractured spring.

- Feasibility study for rotor molded polyethylene.

- Microstructural analysis of heat resistant materials.

- Analysis of a joining tool.

- Analysis of printed circuit board copper plating thickness.

- Analysis of enamel, solder, electroplated and hot dip galvanised coatings.

- Defects in aluminum castings.

- Environmental stress cracking in polycarbonate.

- Curing kinetics of thermosetting resins.