Understanding biomolecular interactions is central to a many research areas spanning science and engineering, including understanding and finding new treatments for diseases, developing new products (e.g., bioplastics, 3D printed devices), understanding and protecting our environment, and developing and utilising new technologies (sensors, NMR drug detection, non-invasive scanning).

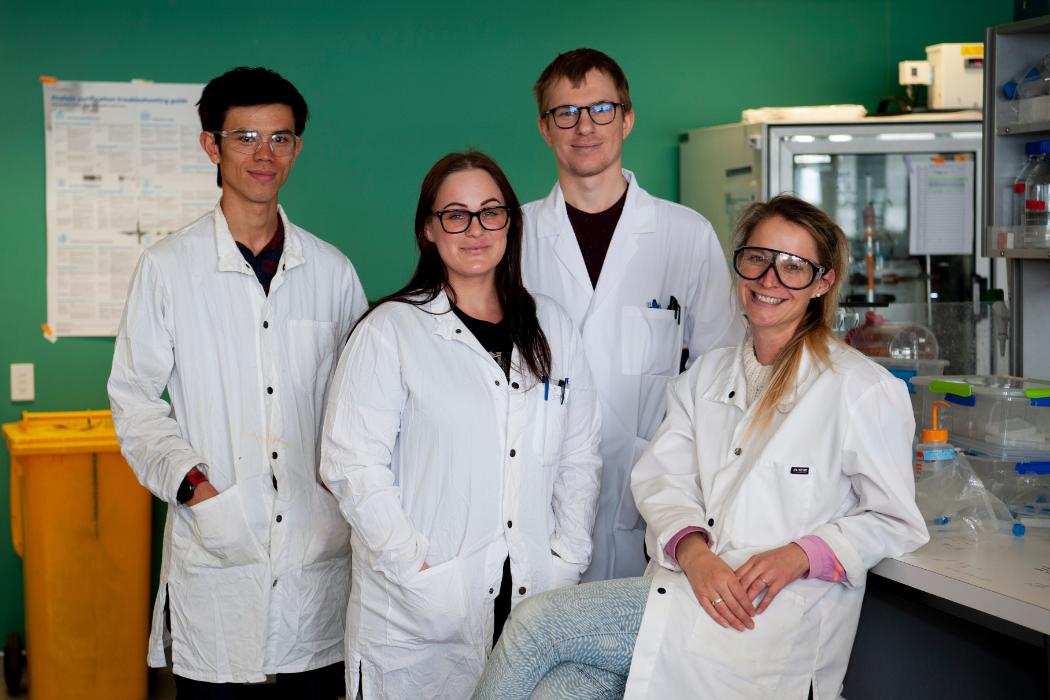

While BIC is based at the University of Canterbury, our 70+ membership include researchers from different New Zealand universities, Crown Research Institutes and Callaghan Innovation, plus a growing number of international collaborators.

Check out our team section to meet our researchers.